Good brews need good fermentation and conditioning practices. Getting it wrong will inevitably result in a poor drink. What I followed in the past, was the classic fermentation schedule, as described in the text book by Ludwig Narziß.

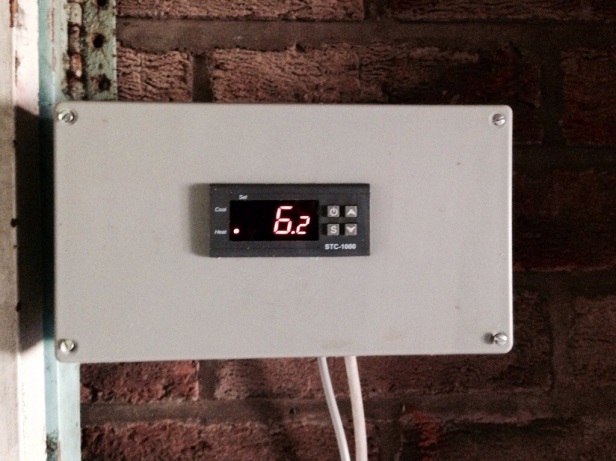

I’m lucky to have a cycliconical fermenter, mounted in an old Indesit fridge with a STC-1000 temperature controller attached to a probe inside the liquid (I found this gives more accurate measurements than on the outside).

Speidels Kellermeister is superb value for money and very well thought through. The fact that the lid is not screwed on but simply tests on a deep ridge (bacteria won’t make it through), makes open fermentation practices and skimming of the Kräusen quite easy.

Speidels Kellermeister is superb value for money and very well thought through. The fact that the lid is not screwed on but simply tests on a deep ridge (bacteria won’t make it through), makes open fermentation practices and skimming of the Kräusen quite easy.

Traditional Cold Fermentation Schedule for bottom fermenting yeast

According to Narziß the yeast is pitched at 6C and the thermostat is set to 8C. At this stage the heating element is switched off and the exothermic reaction of the yeast will cause the temperature to rise to it’s limit of 8C naturally.

Once the temperature has been reached the yeast soon enters it’s most active state of high Kräusen (highest propagation state). I always make a little more than fits into the conditioning tanks and this extra volume of extremely busy yeast is now earmarked for adding to previous batches who are in secondary fermentation. Adding this super reactive yeast to secondary fermenting ones will help it break down unwanted products such as Diacetyl better and produce finer, more rounded beers. This technique is called Kräusening and I find it quintessential for producing great Helles. The results were stunningly superior, so much that I am soon considering this for my Ales and Wheat Beers as well!

Once the beer is fermenting happily along at 8C it stays at that temperature for a couple of days (3-4) until the attenuation reaches about 55%. Once past this goal post, I lower the temperature to 6.5C and the following day to 5C. Once at 5C the attenuation should be 58-60% and I am getting ready to harvest the yeast and transfer to a lager vessel. Transferring this still fermenting beer is called “Grün Schlauchen” (Green Racking) since the young unfinished pale beer now contains a green haze.

My transfers happen in a relatively closed system but it is not necessary to purge the receiving vessel of oxygen. This oxygen will be consumed as fermentation completes. Note that the yeast may already be a bit tired at this stage, and that’s why the injection of fresh yeast in it’s most active state is so beneficial (Kräusening).

My transfers happen in a relatively closed system but it is not necessary to purge the receiving vessel of oxygen. This oxygen will be consumed as fermentation completes. Note that the yeast may already be a bit tired at this stage, and that’s why the injection of fresh yeast in it’s most active state is so beneficial (Kräusening).

A little note on Kräusening

The principle of this technique is very simple. As the yeast moves towards it’s final attenuation, it is not as active any more and the propagation state has slowed down dramatically. Brewers figured out that by adding new yeast in it’s highest propagation state helped clear out the beer faster, reduce the necessary conditioning time and produced beer with a superior taste.

Sometimes it is mistaken for a carbonation technique because of the Reinheitsgebot. I am quite perplexed at seening some renowned authors misrepesenting this. Let’s be clear. It is not. One can carbonate beer via other methods and operate perfectly within the realms of the Reinheitsgebot. Kräusening is used to assist the fermentation to break down compounds such as Diacetyl (amongst other products) and produce a more rounded, polished beer.

Other authors make it a very mathematically intensive exercise. It doesn’t have to be. I use a “Spundapparat” and set the pressure valve to 0.8 BAR. The amount of fresh beer added to the now conditioning beer is about 12-20%. I found 12-15% sufficient. It’s really not that hard and I urge you to try it out!

Once final attenuation is achieved, the liquids temperature is lowered even further to undergo the long process of conditioning. The usual temperature range is +3 to -2C, but it should be noted that (although the beer clears faster at the higher temperatures) any temperatures above 2C will result in a less refined product. I usually settle for 0C to 1C with 0.4C tolerance. Some prefer to lager at -1C but I didn’t notice much difference. Care must be taken not to reduce the temperature of the yeast too fast. Anything above 3C within 24 hrs can apparently cause it to go in a state of shock and produce unwanted by-products.

Once final attenuation is achieved, the liquids temperature is lowered even further to undergo the long process of conditioning. The usual temperature range is +3 to -2C, but it should be noted that (although the beer clears faster at the higher temperatures) any temperatures above 2C will result in a less refined product. I usually settle for 0C to 1C with 0.4C tolerance. Some prefer to lager at -1C but I didn’t notice much difference. Care must be taken not to reduce the temperature of the yeast too fast. Anything above 3C within 24 hrs can apparently cause it to go in a state of shock and produce unwanted by-products.

Adjusting IBU levels for lagering

Manchester water is extremely soft. In Bavaria we call soft water the “hop eater”. This means that recipes need to adjust upwards the IBU scale a bit. Also, the long conditioning phase also breaks down and rounds off the hop bitterness even further. Up to 25% actually and I found this a very good rule of thumb when working out bitterness levels for lagers. Bavarian Helles is very low on IBU’s and you can imagine how awful it tastes when there is not sufficent hop bitterness to balance the malt. Thus, a Helles that has a bitterness of 18 IBU really needs to be hopped to 24IBU. The bitterness will go down quite a bit during the lager phase.

That’s the style. A great Helles is a crisp, refreshing lager where neither the malt nor the hops dominate. Dortmunder is a similar style, albeit at a much higher alcoholic strength.

Time Scales

How long should one lager the beer? Kunze gives the following rule of thumb: “for every degree Plato, one should lager it for a week”. This would give a 12° Plato beer such as Pilsner Urquell a lager time of 12 weeks. However, Narziß is a little more specific and gives the following guidelines

| Type | Original Gravity | Time Frame |

| Helles/Pils | 11-12% | 4-8 weeks |

| Export | 12.5-14% | 6-12 weeks |

| Festbier | 13-14% | 3-6 months |

| Dunkel/Märzen | 12-13% | 4-6 weeks |

| Dark Export | 13-14% | 6-8 weeks |

Summary

- Pitch at 6C and let rise to 8C

- Ferment at 8C until attenuation is 55% (about 4 days)

- Then lower by 1.5C every day until at 5C

- Harvest yeast slurry

- Transfer to lager vessel

- Spunden

- Continue secondary fermentation at 5C

- Don’t forget to Kräusen, it’s perfectly ok to do this even after secondary fermentation is complete.

- Lager at 0C for at least 4 weeks

There are ways to ferment it quicker without sacrificing quality… or so there is that claim. I’ll try that next…

Hi, I have been reading through your blog, and really enjoy the information you are sharing. Thank you! I have a question regarding kräusening. So to be clear, you add your kräusen once you have lowered the main batch to 5C? Do you slowly lower the temp of the kräusen also?, or do you add it when it’s at primary fermentation temperature (9-12C depending on yeast) into the colder main batch?

Thank you. I look forward to reading about your future brewing.

Nick.

LikeLike

Hello Nick, thank you for the kind words. You never want to shock the yeast. It’s usually never added to the main fermenter but dosed at transfer into lager tanks. It certainly isn’t a bad idea not to have too big a temperature drop. 9-12C is a good temperature for a quick ferment to test the ballpark of a recipe. I am still a proponent of cold fermentation for the quality stuff (7-9C max). There the temperature drop isn’t as high and often well within range, esp when fermenting at 7C. This may not be everybody’s cup of tea though. A DO meter for establishing correct oxygen levels as well as a sufficient high cell count are mandatory. I might share my thoughts on this pending outcome of some experiments. Hope this helps.

LikeLike

Thank you for the reply. That is very helpful indeed. I am brewing a Helles this following week with WLP 833 yeast, 98% pilsner malt, 2% carahell. I intend on doing a double decoction hochkurz mash, and fermenting at the schedule you have shown here (perhaps at the maximum of 9 degrees to be safe).

I will make a good yeast starter, so cell count will be good. But unfortunately I do not have access (yet) to a DO meter, or pure oxygen. Alas, I am left to shake my wort to introduce oxygen. Is it possible to reach enough dissolved oxygen via a vigorous and lengthy shaking of the wort to facilitate this fermentation schedule?

Thanks again.

LikeLike

A few people I know, and in possession of a DO meter, claim to have reached 6-8 mg/l shaking – which will be enough.

I would not use pure O2 without being able to measure. It’s very easy to over-oxygenate and cause damage.

LikeLike

If you get the pitch rate right then you can (and should) ferment lower. About 1 WLP vial per 10l is not unusual (or 250ml of slurry in 50l). Don’t let it cool overnight, it’s a bad idea. If you can bring it to 5C then pitch at that temp, then raise to 8C over two days. You can measure begin of fermentation with a pH meter and note the pH drop (even though you may not yet see anything).

LikeLike